Quality Control in All Procedures

At KSSDISPLAY, we take pride in our LED screen production process, which includes strict requirements enforced in our workshop and continuous employee training to ensure smooth project execution.

To maintain our high-quality standards, we hire experienced quality inspectors to check and verify that every product meets our quality expectations. Throughout the production process, a quality inspector is present at the end of each production step to ensure there are no issues before moving on to the next step.

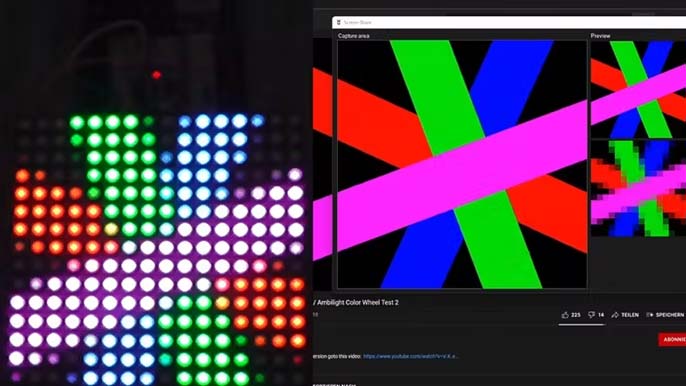

Our quality inspectors are highly trained and have extensive knowledge of the LED screen manufacturing process. They carefully examine every aspect of the LED display, including materials, production techniques, and final assembly. Our inspectors also use advanced testing equipment to identify any defects or irregularities, ensuring that only the highest quality products leave our factory.

At KSSDISPLAY, we are committed to providing our customers with reliable, high-quality LED displays that exceed their expectations. Our rigorous quality control process ensures that every LED display we produce is of the highest quality and will perform flawlessly.

Qualified Matieral

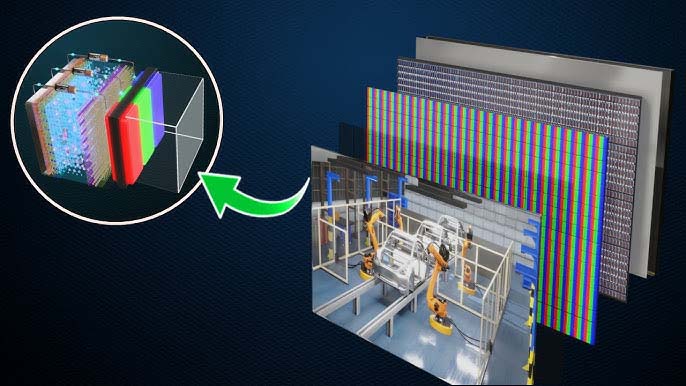

The final performance of the quality of the LED display depends on the quality of its raw materials. We must confirm the choice of raw materials before production.

Strict Testing

At each step of mass production, our engineer will take tests to reach a higher quality standard. Besides regular testing, we will take additional tests for displays used in different environments.

Professinonal solutions

When arranging an order with the production manager, it is necessary to list the complete requirements to ensure that it is all to the requirements of the customer’s order.

KSS Display Provides Best Products

it is essential to establish a quality control plan to ensure the production of high-quality LED displays.

Quality control plays a crucial role in LED display manufacturing. It is essential to plan the quality inspection process, approve the raw materials, and confirm the specific production requirements with the factory’s responsible personnel before production starts.

In addition, it’s crucial to communicate with the customer to check the product details and confirm their requirements. With a comprehensive quality control plan in place, you can minimize the risk of errors, ensure the highest quality standards, and deliver an LED display that meets your customer’s expectations.

At KSSDisplay, we recognize the importance of quality control and have established a rigorous quality inspection process that starts before production and continues throughout the production process. We strive to deliver LED displays that meet and exceed our customers’ expectations.